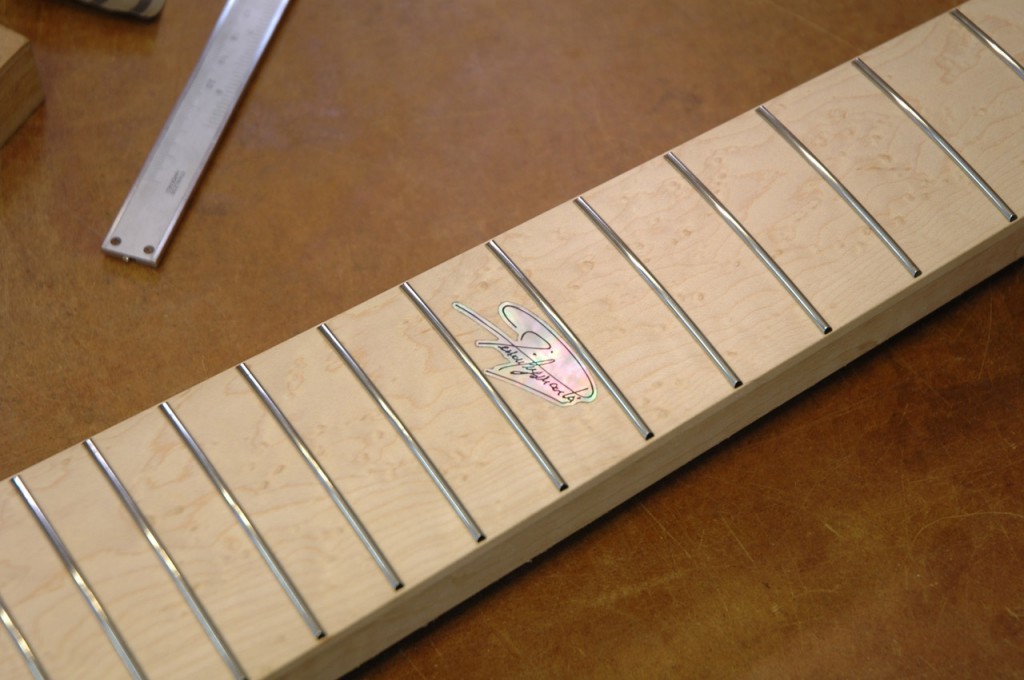

Another bass that will go to Brazil, this time for Fabio Lessa, a great musician who plays with the likes of Gilberto Gil, Preta Gil and Celso Fonseca.

Set neck construction, maple and padauk neck with birdseye maple fingerboard, mahogany body with buckeye burl top, Ele jazz style pickups for a more traditional sound and Bartolini preamp for a not so traditional sound.

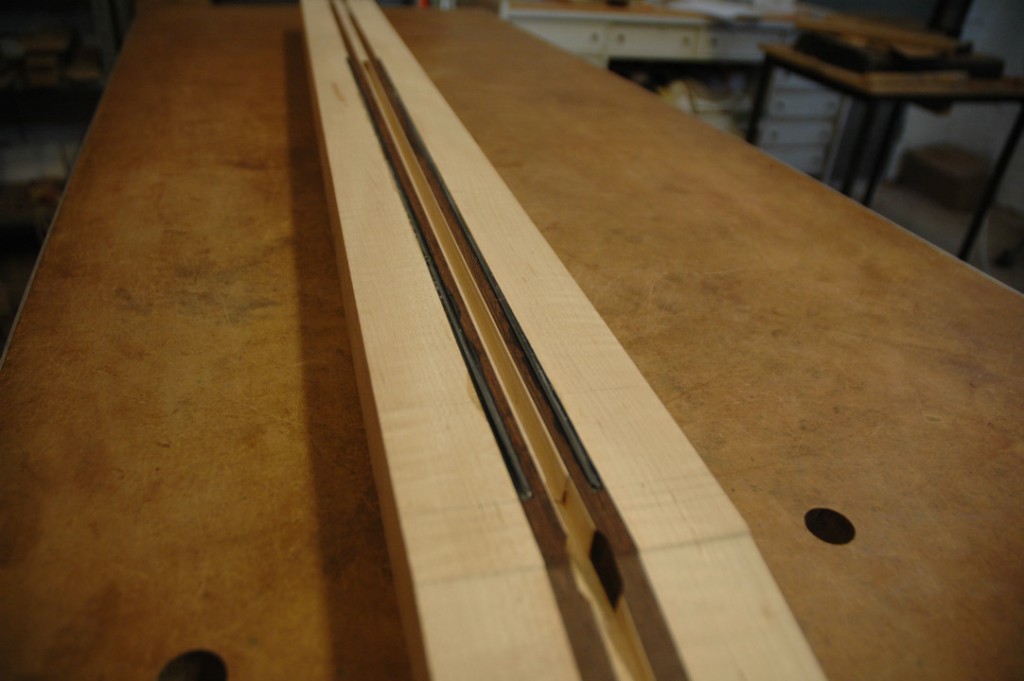

See those black dots? They are ebony. Gotta love wood!

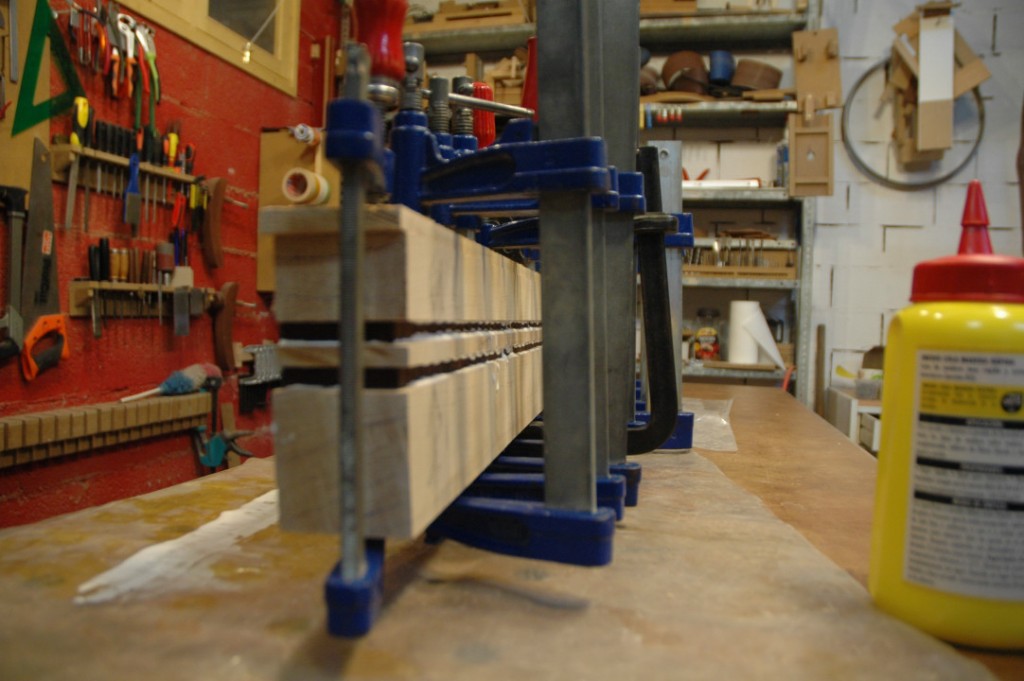

Complicated neck-body glue up.

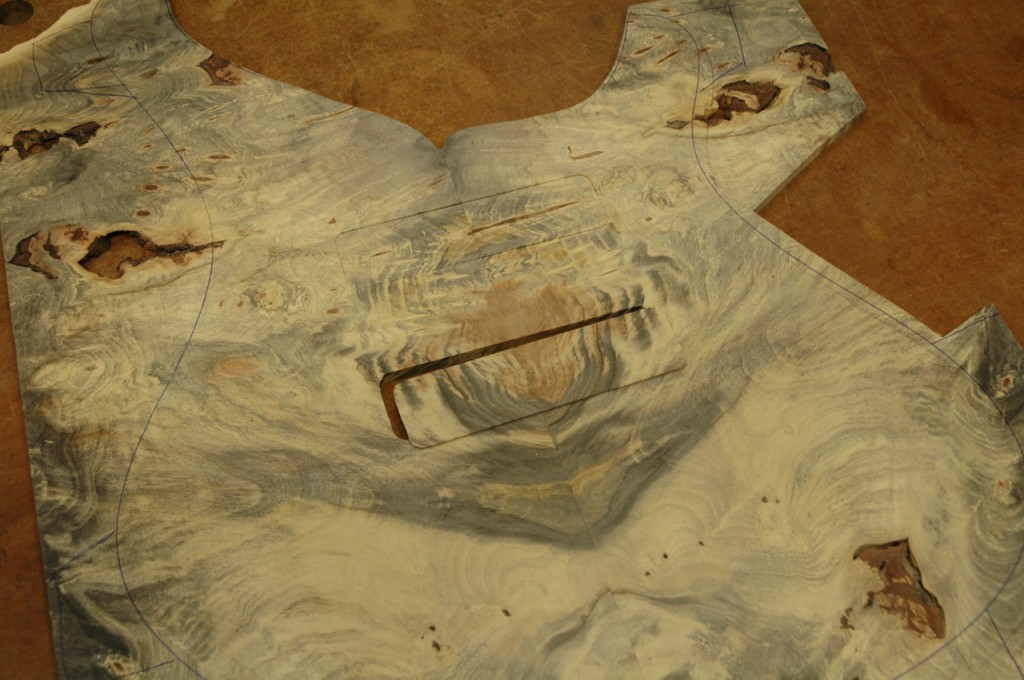

Check out the different colors of that buckeye burl top. Ah, nature…

Almost ready to start rounding the edges.