EACH ELE BASS GUITAR IS SPECIFICALLY TAILORED FOR EACH CUSTOMER. THAT IS WHY EVERY INSTRUMENT I BUILD LOOKS UNIQUE AND SOUNDS UNIQUE.

THE FIRST STEP IS TO SELECT A MODEL. FROM THAT POINT ON, THE CUSTOMER AND I WORK TOGETHER TO SELECT THE MATERIALS AND CONSTRUCTION DETAILS THAT BEST FIT HIS / HER IDEA OF THE PERFECT INSTRUMENT.

I AM ALWAYS INTERESTED IN NEW CONSTRUCTION ADVENTURES, FOR EXAMPLE: MORE STRINGS THAN THE USUAL FOUR, FIVE AND SIX; CUSTOM PICKUP COMBINATIONS AND ELECTRONICS; CUSTOM INLAYS; ETC.

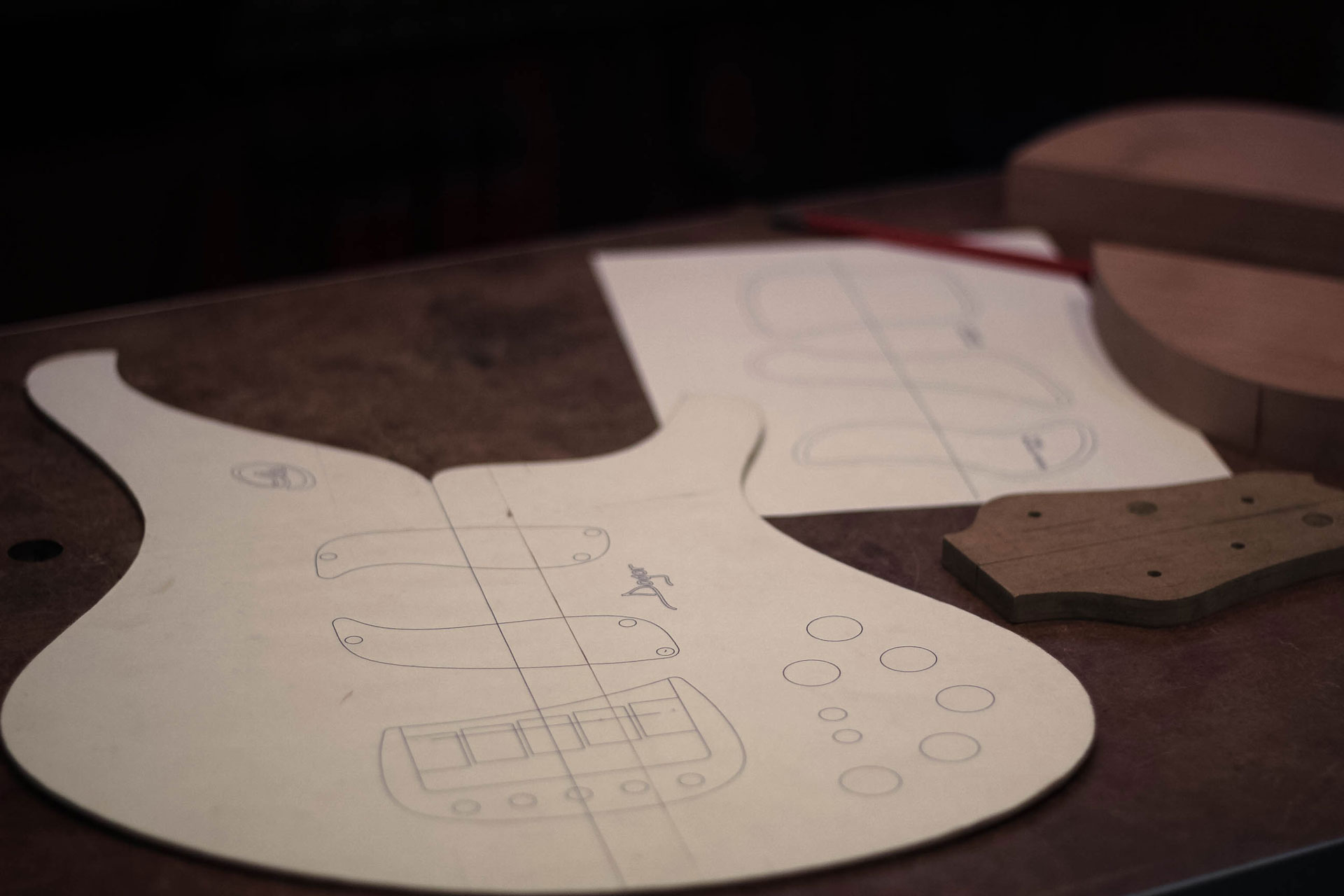

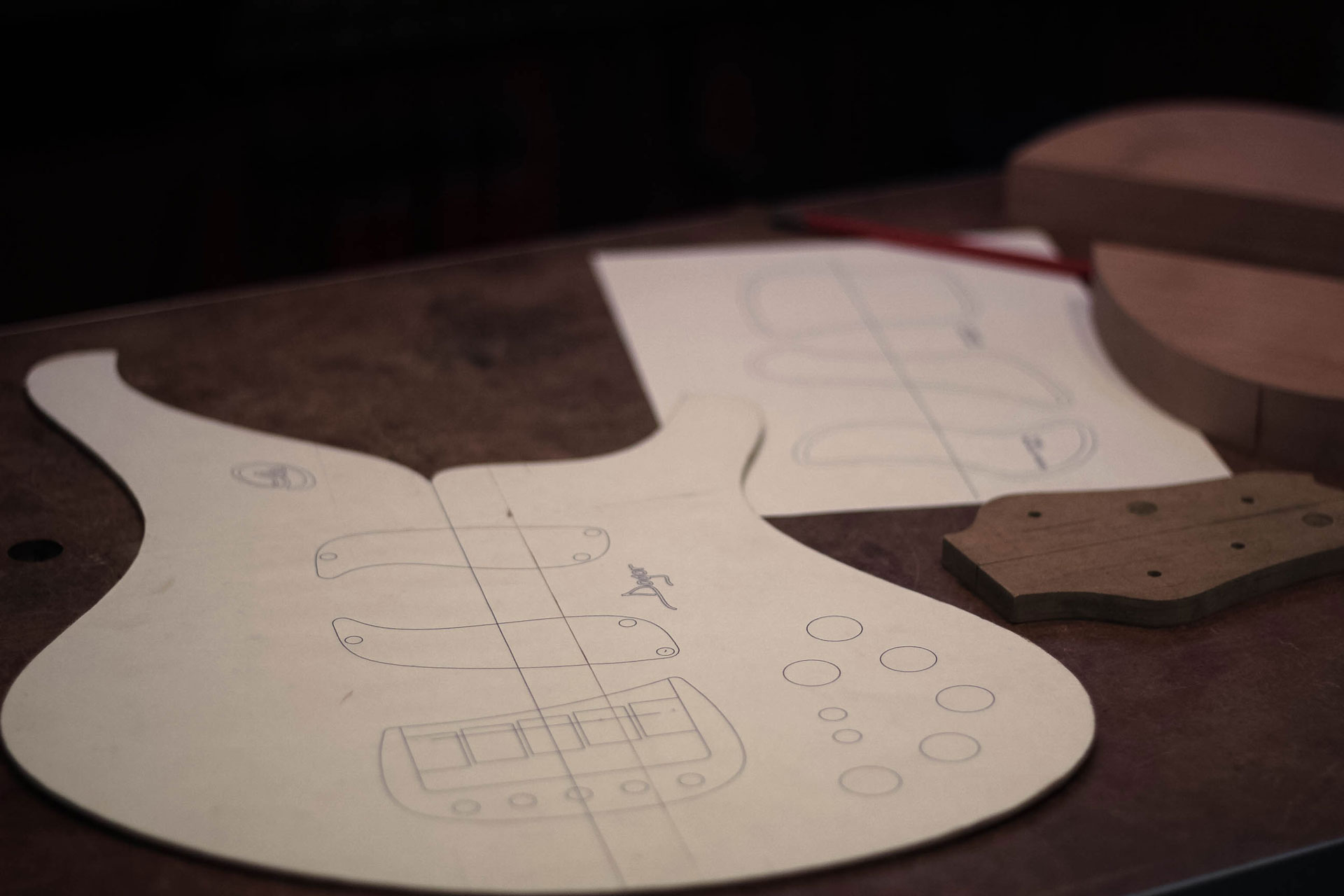

Design

Each of the four models available is shaped with playing comfort in mind. The body is sculpted so it adapts well to most players' bodies, either when playing sitted or standing. The fingerboard does not overlap the body, allowing plenty of room for the fretting hand in the front and in the back of the neck when playing in the highest positions. This allows complete access to all the frets without the need for awkward maneuvers.

Woods

Selecting the combination of woods for a bass guitar is a very exciting part of the construction process, because that combination is one of the most important factors in the appearance of the instrument and definitely the most important factor in its sound.

Maple, alder, ash, mahogany, rosewood and ebony are staples in the electric instrument tradition, but we must not forget the acoustic and aesthetic possibilities of bubinga, wenge, sapele, lignum vitae, purpleheart, birch, walnut, padauk, etimoe and merbau, just to name a few.

Neck

A crucial factor in the playing comfort of a bass guitar is the design of the neck. It can be built with different scale lengths, fingerboard radiuses and back profiles.

The back of the neck can be shaped in three basic profiles: the traditional round profile; the modern flat oval profile, wich suits most playing styles; and the asymmetrical profile, very comfortable for those who play with the thumb behind the neck.

The necks are constructed with multiple parallel pieces laminated together. The correct orientation of the wood grain in each piece and the use of carbon fiber reinforcements ensure that the neck is very resistant to movements related to humidity and temperature changes. Using more than one wood species adds another aesthetic possibility and broadens the acoustic spectrum of the instrument.

Body

The body can be constructed with two basic configurations: solid, for the usual focused sound favored in most modern musical styles, and semi hollow, which gives the instrument a somewhat acoustic sound. The semi hollow body, being much louder than the solid body, is very useful for practicing without amplification.

The top of the body can be made with visually special woods, like flamed, spalted and multicolored pieces.

Neck and Body join

The two different methods I use for joining the neck with the body affect the sound of the instrument in a different way.

SET NECK: In this type of joint, a pocket that matches the base of the neck is very precisely carved in the body and then the two parts are glued together, reinforced with internal wood splices, ensuring a very strong joint. It provides a good balance between attack and sustain.

NECK THROUGH BODY: Another very strong joint, in this case the neck extends through the entire length of the body. It provides extra sustain with a mellower attack.

Bridge

The design and specially the materials of the bridge have a decisive influence in the final sound of the instrument. The industry offers bridges made of brass or aluminium, but not wood. I can make a traditional acoustic style wooden bridge, but that kind of design lacks the possibility of adjusting string action or intonation, which are important when setting up a bass guitar the way the player likes it. For this reason, I decided to design a fully adjustable wooden bridge. This way, the vibrations travel through a circuit made almost entirely of wood, resulting in a warmer sound and eliminating much of the noise of the lower strings. For the moving parts, only very hard woods are used, mostly ebony,hard maple, bubinga and lignum vitae.

Electronics

With the goal of having complete control over the sound of my bass guitars, I build my own pickups, so that I can fine tune them for each instrument. There are different factors that can be combined in a particular pickup: single coils for a traditional bright sound; split, double or stacked coils for a noiseless output; different magnet materials; etc. The pickups can be coupled with the traditional passive electronics or with a preamp for more sound shaping possibilities and higher output.

And to squeeze out all of the possible sounds hidden in the wood, a piezo pickup in the bridge can capture the broad spectrum, acoustic sound of a bass.

Details

Wood is the favorite material of every luthier. Since I am not an exception, I make use of this versatile material as much as I can.

Control knobs, pickup covers, electronics covers, truss rod covers, fretboard inlays and logos are all made of wood, allowing me to turn them into integral parts of the design of the instrument.